Google Colab

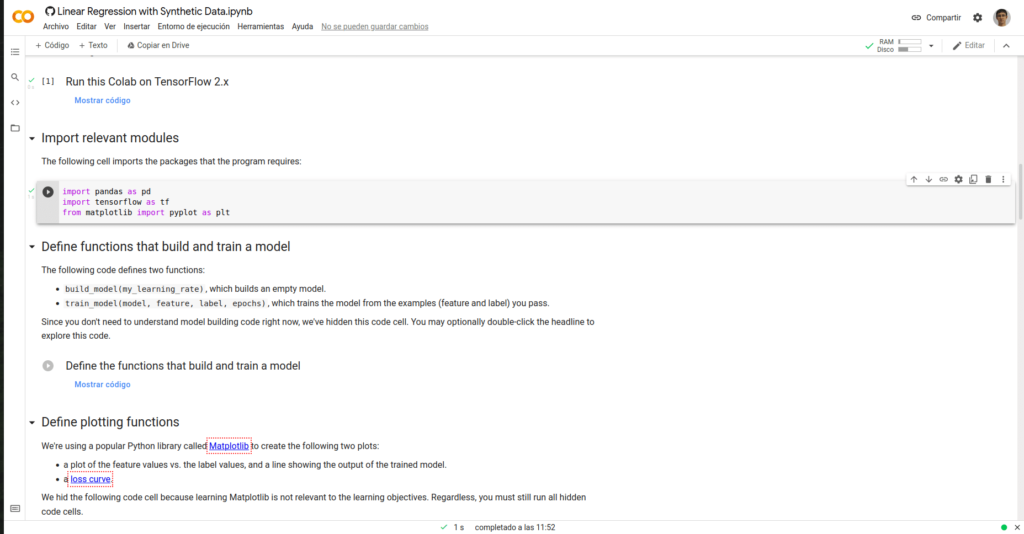

Colaboratory, also called Google Colab is a product of Google Research and is used to write and run Python and other languages from your browser. What it is Here is a beginner’s guide that perfectly complements this article. Colab is a hosted Jupyter, installed and configured, so that we do not have to do anything…

What TinyML is

TinyML or Tiny Machine Learning refers to the use of Machine Learning in microcontrollers. In systems that unlike those used in traditional ML have few resources, are systems that have little CPU, little RAM and extremely low power consumption in the order of magnitude of milliwatts or microwatts. Its official website is the TinyML Foundation….

What is Scratch and what is it for

Scratch is a programming language created by MIT and based on a block-based visual interface, so that it greatly facilitates the programming of children and people without knowledge. It is recommended for ages 8 to 16 years. All of this is supported by the Scratch Foundation, a non-profit organization whose mission is: Our mission is…

Ikkaro is a personal website. Here the way it work. Follow me in @ikkaronet

Science Experiments

This is one of the main pourpouses of the web. Ikkaro was born thinking in home made, diy, science experiments and invents. Is one of the main themes of the web

Repairs

Open Hardware

Arduino, raspberry, IoT, and their world.

Machine Learning and Deep Learning

Artificial Intelligence, how to learn it and use it

Machines, Mechanisms and engines

Engineering. I love engines., specially little hot air engines, like Stirling engines and also the electric ones.

Who I am

My name is Nacho Morató I’m an spanish engineer. You can know more about me in my profile.